LOCAL CIP

In the food sector, the term "CIP" refers to "Clean-In-Place", a method of cleaning equipment on site without dismantling it. A CIP room is an area or room in a food production facility where the CIP system is located. The CIP process uses cleaning and disinfecting solutions that are pumped through the equipment to be cleaned, eliminating food residues, micro-organisms and other contaminants.

OUR MISSION

The company wanted to convert part of the building's roof, as well as the top floor, to create a new CIP area for cleaning and disinfecting storage tanks.

We were commissioned to manage all the utilities (excluding the process) for this new plant, as well as to manage and create the 3D BIM management model.

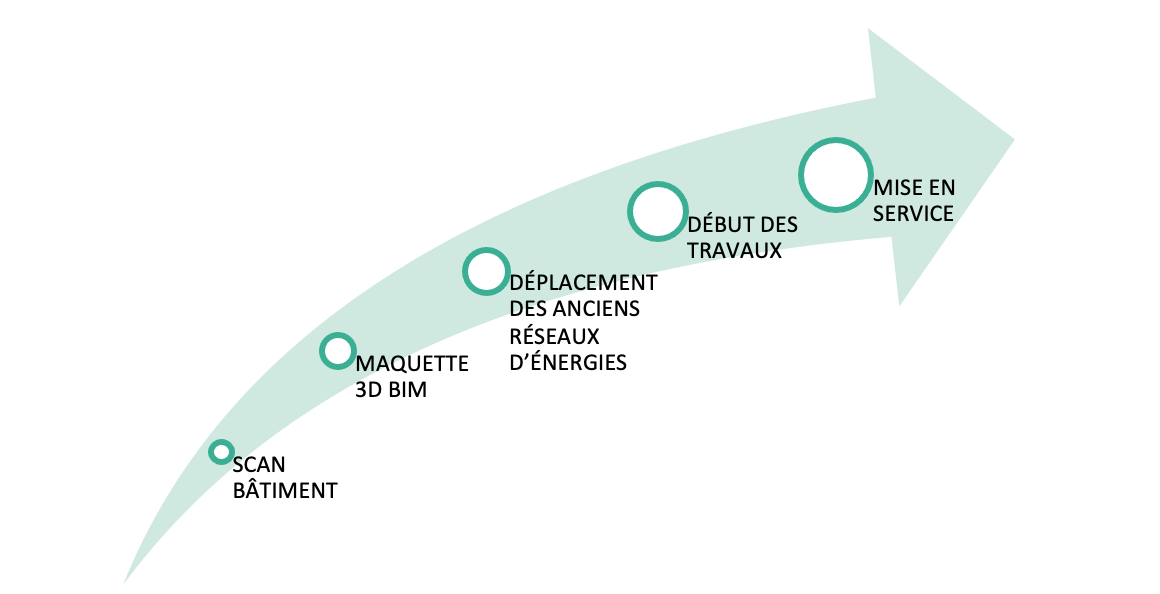

An initial operation to relocate the old energy networks had to be carried out beforehand to make way for the roof opening.

PHASES

The project took 1 year to complete and commission. The new CIP room now boasts a total of 6 tanks, including 3 new tanks (2 soda tanks and an acid tank, each with a capacity of 15,000 liters), to complement the 3 pre-existing tanks, a 20,000-litre water recovery tank, a 10,000-litre hot water tank and a 5,000-litre fresh water tank.

All the tanks are connected by a network of vents that discharge the air onto the building's new roof. An evacuation route has been created around the room to guarantee the safety of users.

Several energy installations are present in this new CIP room:

- Ventilation

- Vapeur blanche 5 bars

- Eau froide sanitaire

- Air comprimé

- Eau glycolée de process

- Electricité

.

SECTOR

Food

YEAR

2020

WHAT WE DID

Creation of a new CIP room for cleaning and disinfecting milk storage tanks.

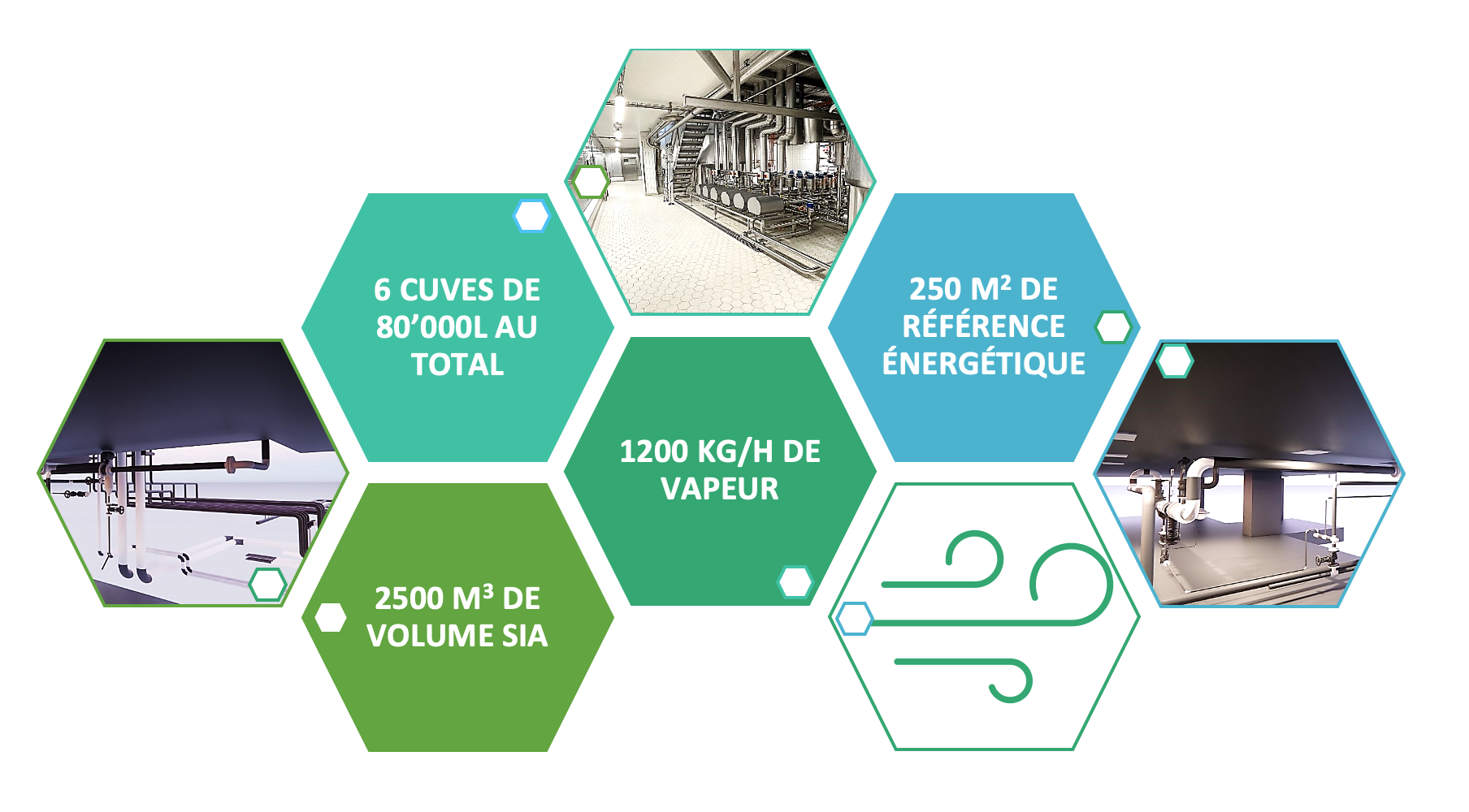

IN FIGURES