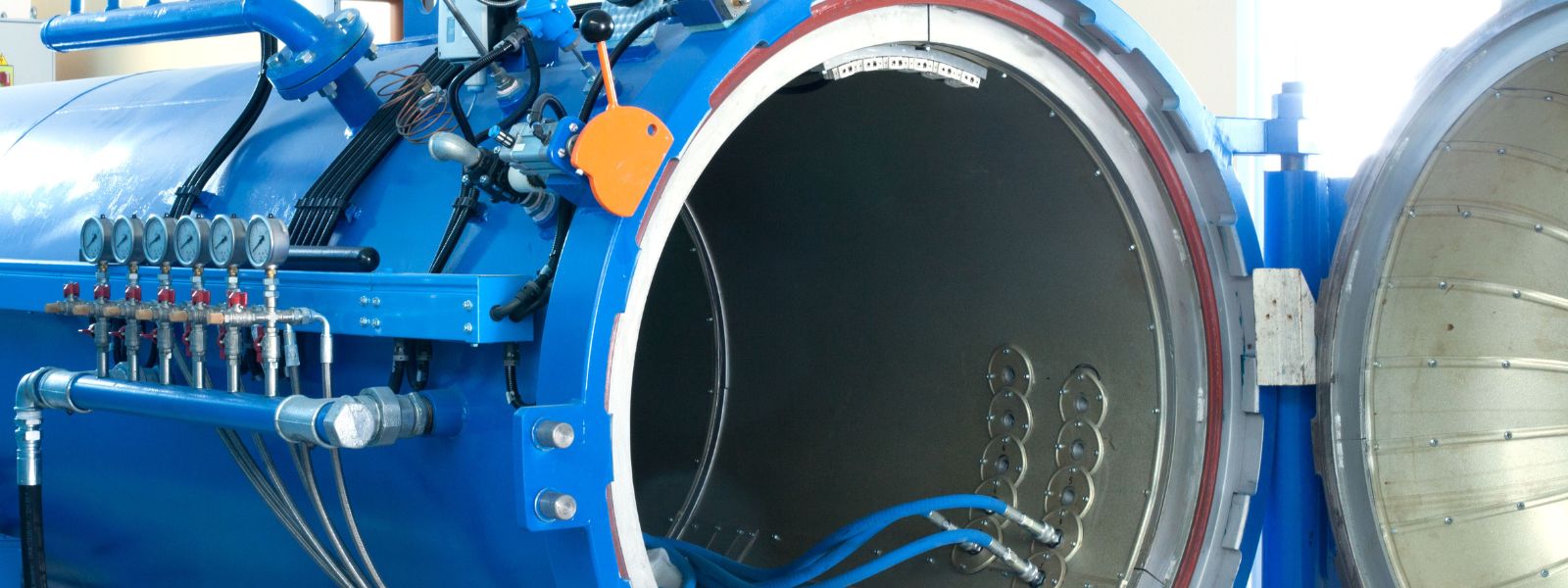

AUTOCLAVE

The autoclave is a sealed chamber used to sterilize objects by exposing them to pressurized steam at high temperatures (generally between 121°C and 134°C). The autoclaving process is widely used in the medical, dental, veterinary and scientific research fields, as well as in certain industries to sterilize instruments, supplies and liquids. The use of pressurized steam enables high temperatures to be reached, killing micro-organisms, including bacteria, viruses and spores.

MISSION

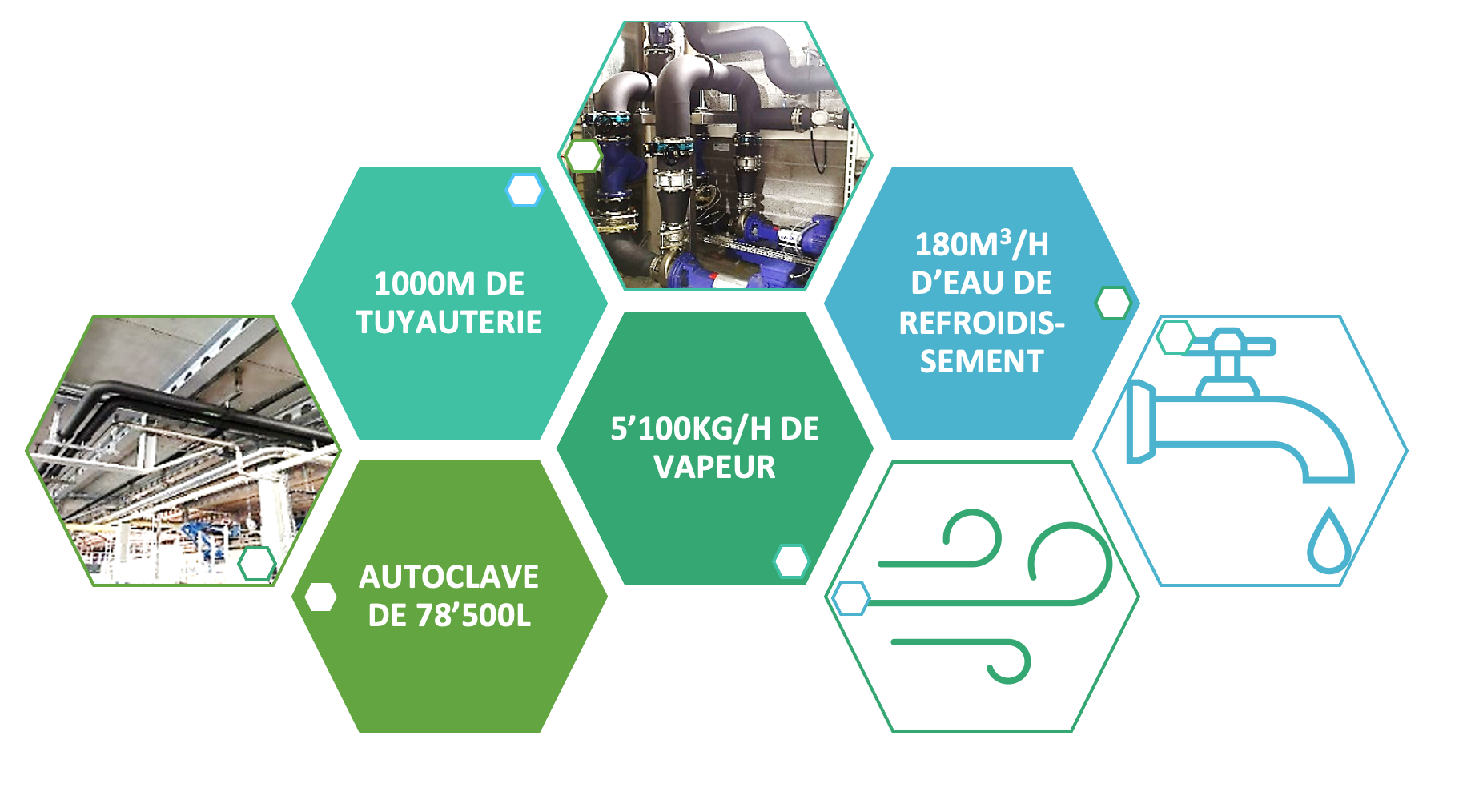

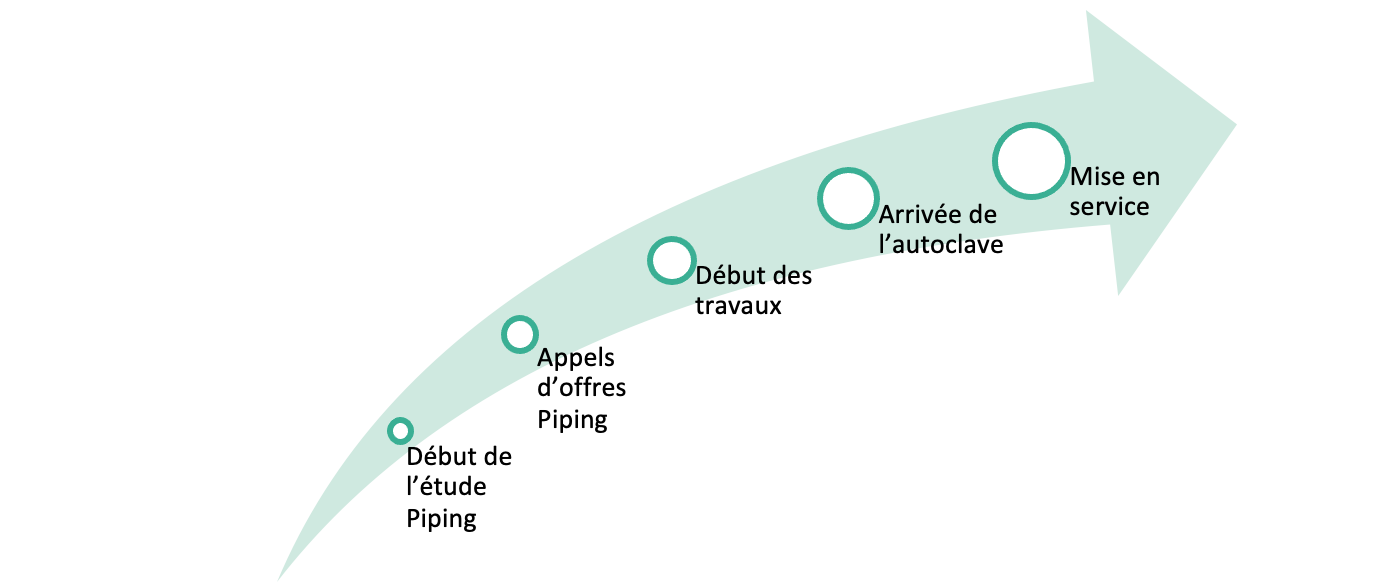

We were entrusted not only with the entire detailed design of the new autoclave, but also with the supervision of the construction phase and responsibility for the design of all utilities surrounding the new plant, i.e. steam, condensate, hot and cooling water, and finally the compressed air system.

The new autoclave was installed in just 10 months. The new area features a 78,500l autoclave, as well as an 8,000l compressed air tank. There is also a compressed air room, a steam room and cooling towers.

Various energy networks within the project perimeter have been adapted:

- Compressed air

- Steam & Condensate

- Cooling water

- Reverse osmosis water

- Drain flow

- Vents network

All these installations have been modified from existing technical plants.

SECTOR

Pharma

WHAT WE DID

Installation of a new sterilization unit in the form of an Autoclave.

PHASES

IN FIGURES